About

RICH SKY EYELASH- Where Precision Meets Passion.

We don't just manufacture eyelashes - we craft confidence.

As a fully integrated factory and exporter, we control every aspect of production from raw materials to finished products, ensuring unparalleled quality and consistency for beauty brands worldwide.

Our Story.

Founded in 2020, we began with a simple mission: to create exceptional eyelashes that empower beauty and self-expression. Today, we partner with many global brands, combining traditional craftsmanship with innovative technology.

Why We're Different?

Vertical Integration: Complete control from fiber selection to shipping

Quality Obsession: Every lash is hand-inspected against rigorous standards

Innovation Drive: Our R&D team continuously develops new styles and techniques

Global Mindset: Products designed for international markets and standards

Our Commitment

We're more than a supplier - we're your strategic partner in beauty. Whether you need OEM manufacturing, custom designs, or reliable volume production, we deliver excellence in every detail.

Your Ultimate Private Label lash Manufacturer

Strict Raw Material Selection:

We focus on the raw material selection, we only utilize the top-rated raw material to determine the best quality of the false lashes. Real mink fur, synthetic fiber, newly-discovered hemp fiber is ethically sourced to ensure the quality.

Lash Manufacturing:

Each pair of false lashes are manufactured with exquisite handcrafting technique and strict machine processing. We are aiming to work out the high-end eyelashes to meet top standards. All lashes are checked seriously.

Stable Productivity Guarantee:

We have 30+ advanced production lines to ensure the stable supply chain with big capacity, and we have enough stock lashes in our warehouse. So that you can get your qualified lashes with fast shipping.

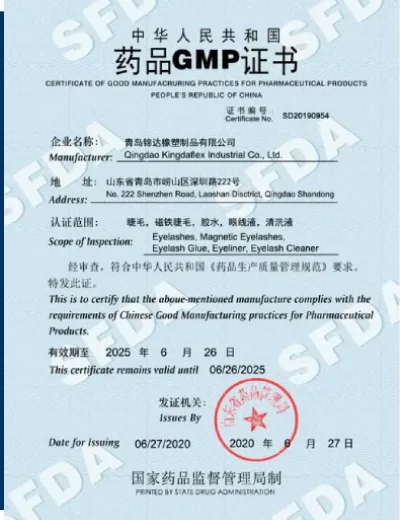

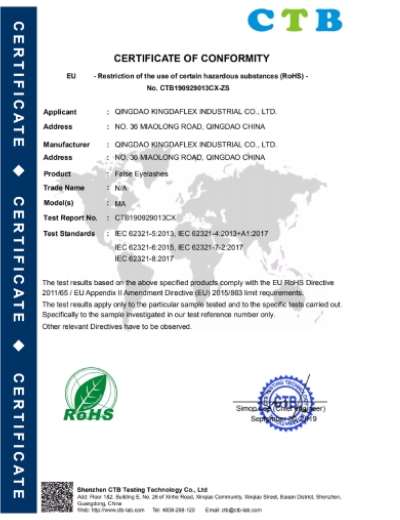

Our Certificates

Eyelash Manufacturing Process [Brief Guide]

Raw Material

We are serious about selecting the raw material for lash production. To ensure the top rated quality form the base root.

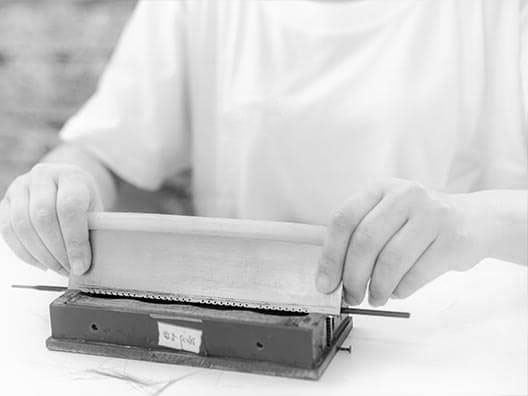

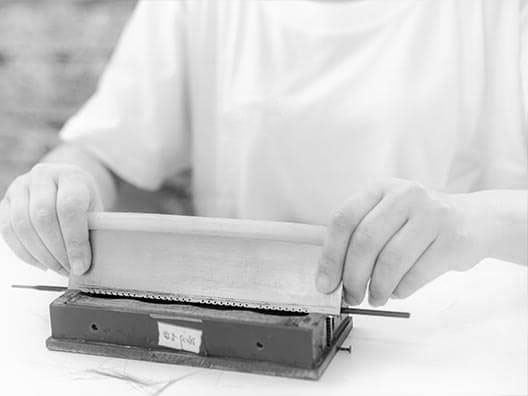

Align Lash Fur

Use the mold to align the lash fur materials, to make them aligned well to form the lash strips. And remove away the mass lash hair.

Form Lash Clusters

Then to form the lash cluster fibers in a good shape. Stick the lash clusters on the lash band, using the adhesive lash glue.

Make Lash Styles

Then make the lash styles, to cross some layers of the taped lash clusters to create different lash styles.

Cut to Shape

Use the iron stick to cut off the other half, not the lash band, to leave the complete lash strips glued on the lash band.

Curl Lashes

Curl lashes using the steel sticks with heating, this step is very important to create vividly natural lash curls.

Remove Steel Stick

After heating process, we need to remove the finished lashes from the steel stick. Then apply some lash glue to the lash band.

Install Lashes

Finally, install the strip lashes to the lash tray, to keep them in a good structured shape all the time before packaging process. Boom, lashes are made!